Invest in Advanced Design

Redefining Performance for Rock Breakers and Post Drivers

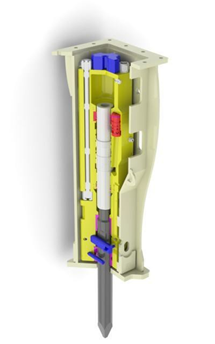

Thor employs an advanced piston-driven mechanism, powered by the renowned SB Power Cell that has dominated the industry for over 50 years. Operating at a nitrogen gas pressure of 16.5 bar, this mechanism delivers unparalleled impact Joules.

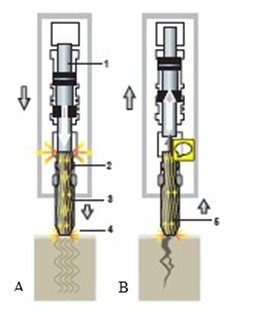

As hydraulic oil flows from the host machine into Thor’s power cell, it propels the piston within a nitrogen gas chamber. This hydraulic-nitrogen synergy sets the stage for generating substantial impact force. The pressurised hydraulic oil acts as the driving force, propelling the piston downward. This swift motion compresses the nitrogen gas, storing potential energy.

Upon reaching peak pressure, the hydraulic valve opens, triggering a controlled impact as the hydraulic oil is released. This dynamic process harnesses both hydraulic pressure and the stored compressed nitrogen energy. This energy combination propels the piston onto the rock chisel or post tool with formidable blows of impact Joules. Consequently, a sequence of precisely controlled impacts ensues, effectively driving the rock chisel or post tool with optimum force and accuracy. This capability ensures efficient material breakage or installation. The dual-source energy release equips Thor’s rock breakers and post drivers to adeptly adapt to diverse operational demands.

The integration of hydraulic flow control confers a significant advantage. The host machine’s operator can dictate the driver’s speed with precision by regulating the hydraulic flow. By adjusting the hydraulic flow rate, operators can either expedite or moderate the driving action. This adaptability optimally suits various tasks and materials. This level of control empowers operators to tailor the impact intensity to match job-specific requirements, thereby enhancing both operational efficiency and precision.

Minimal Moving Internal Parts – Simplifying Maintenance

THOR’s design philosophy prioritises ease of maintenance. With only two moving internal components – the piston and the valve – maintenance procedures are minimised and streamlined, resulting in reduced downtime and low associated costs. This simplicity extends to disassembly and reassembly, facilitating swift component replacements. This design nuance significantly contributes to prolonged operational uptime, ensuring that maintenance tasks when required are efficient and effective.

Precise Blow Force

Uncompromising Durability

THOR’s commitment to uncompromising durability is exemplified by the use of premium high-strength heat-treated alloy steel in the manufacturing process of our rock breakers. This alloy steel offers an exceptional combination of tensile strength, hardness, and resistance to wear and abrasion. This not only extends the operational life of the equipment but also ensures optimal performance even under the most demanding working conditions. The alloy’s inherent toughness reduces the risk of fractures and deformations, delivering robustness that resonates across diverse applications.

THOR’s commitment to quality is also reflected in our rust resistant nickel plated bolts, flash chromed pins and bosses as well as top quality industrial painted power cells.

THOR’s heavy duty mounts for skid steers, tractors, loaders, and telehandlers weighing 200 – 250kg are made from 16mm and 20mm plate steel and together with their slanted legs and are the most stable on the market. The mounts are quick and easy to attach and when detached from the host machine and when not in use they stand anchored where left, with no danger of them falling over.

The Advantages of Engineering Excellence

THOR’s advance design yields a multitude of advantages. Our focus on robust materials and engineering precision enhances equipment longevity, minimising replacement cycles.

The synergy between hydraulic and nitrogen driven impact results in unparalleled force, enabling efficient material breakage and excavation, the simplicity of our design translates to minimised maintenance demands, ensuring operational continuity.

With THOR rock breakers and post drivers, you benefit from precise, powerful, and reliable equipment that maximises productivity, reduces costs and stands as a testament to innovative engineering excellence.

Elevate your operations today with THOR Rock Breakers and Post Drivers – where advanced design defies a new standard in construction equipment performance.